Product Details

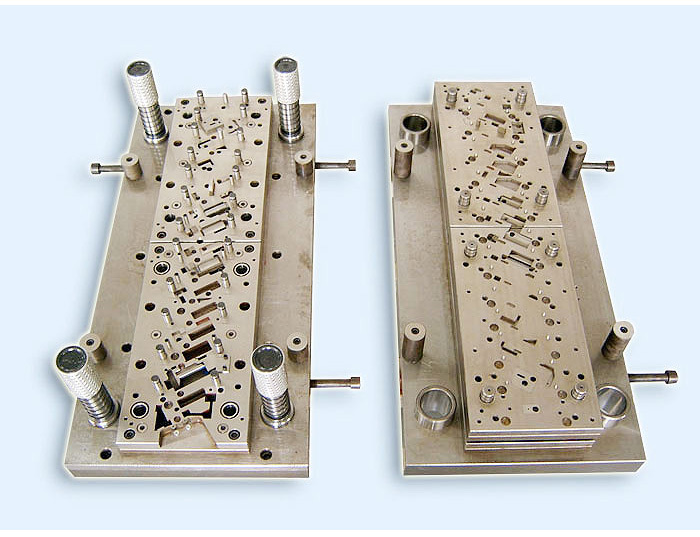

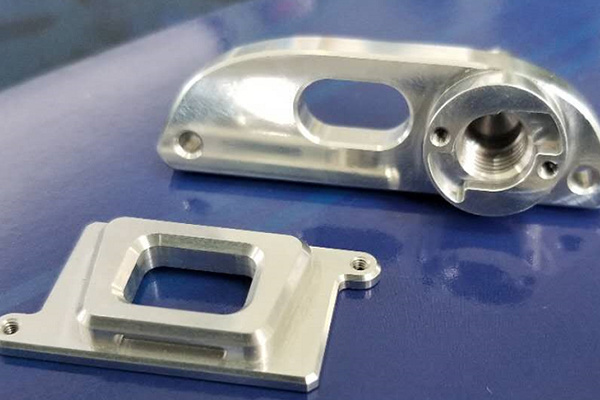

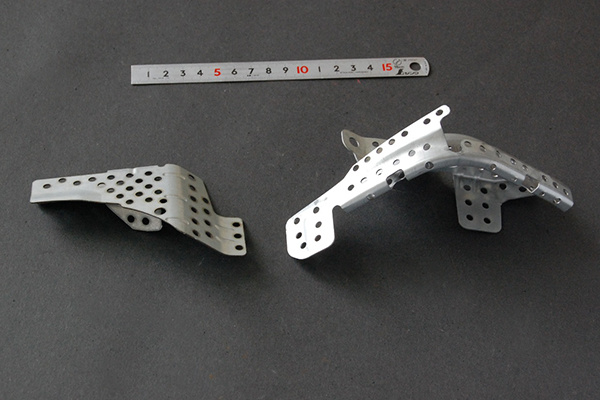

Product function: Through automatic feeding, all the forming requirements of the part are completed on a pair of molds. The punching process includes punching, cutting, flanging, marking, bending, forming and cutting.

Product material: The mold forming component material adopts SKD11 and the hardness reaches HRC62 after cryogenic treatment.

Product features: Realize one-time molding of complex parts, reduce processing procedures, improve production efficiency, and reduce manufacturing costs.

Design points: There is less waste in layout, and each molding component is designed with inserts and vacuum coating is applied to facilitate maintenance and increase mold life.

Product process: All mold templates are subjected to stress relief treatment, and the forming surface and knife edge surface are respectively processed by cutting, trimming, three slow wires and forming grinding to ensure that the surface roughness is below Rz0.6.

Key words:

previous

previous

ONLINE MESSAGE

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Related Products