An Integrated Scheme of Measurement Platform

release time:

2022-09-16 13:53

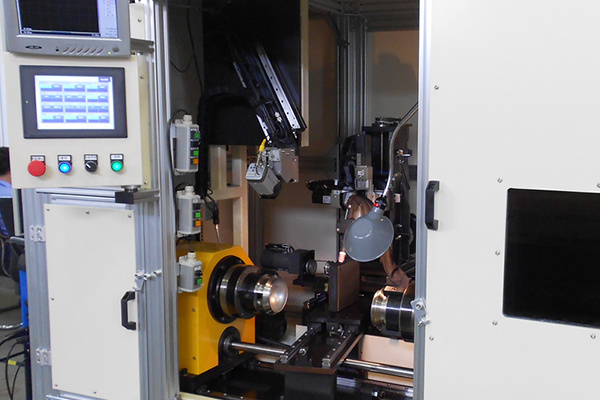

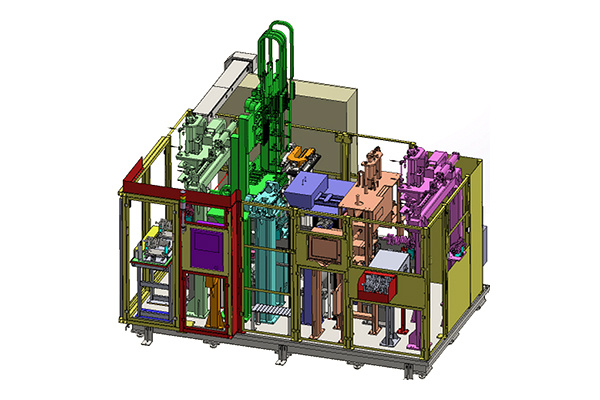

In the process of localization of automobile engines, we urgently need to solve the quality control of parts in the process of processing, and the precision measurement of all aspects of parts is particularly important. To this end, we propose an integrated solution of a measurement platform, which has been widely used in the field of automobile engine manufacturing and has become an indispensable supporting equipment for testing. Through the effective integration of the detection fixture and the equipment system, the measurement efficiency of each detection data is greatly improved, and the measurement of different processing surfaces can be completed in one clamping, and the operation of the operator is more flexible and convenient.

The problems solved by this solution and its own characteristics:

1) The unique air path design replaces the air bearing, which greatly reduces the cost and breaks through the bottleneck of the heavy load of the air bearing.

2) The application of independent non-connected vibration isolation large load foot pads, the adjustment level is light and convenient, and the vibration isolation effect is excellent.

3) The combination of linear bearings and self-aligning bearings through a special mechanism to achieve multi-dimensional free movement is the core design of the air flotation system.

4) This air-floating sliding table can meet the motion of X, Y axis and rotation axis at the same time, and all have fine-tuning mechanism, and the adjustment accuracy is 0.01mm.

5) The maximum load of the air-floating mobile sliding table is 500Kg.

6) The fine-tuning accuracy of each moving axis is 0.01mm.

7) The efficiency of a complete measurement is increased by 80%.

previous

previous

related case